Nowadays, more and more people buy smart door locks, and the analysis of smart door lock materials is more and more, but there are not many professions, either soft papers or their own subjective judgments or yes. Come to a professional.

First, the main material of the current smart door lock application

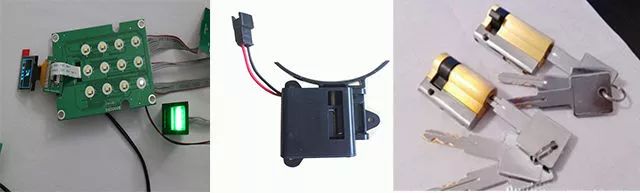

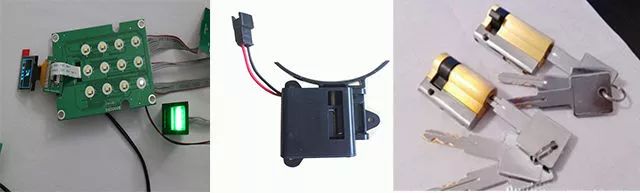

There are many materials that can be applied to smart door locks, especially metal materials, depending on the materials used in the different accessories. The main materials used in the lock body (Fig. 1) are iron, stainless steel and copper; the materials applied on the panel and handle (Fig. 2) are mainly plastic, stainless steel, iron, aluminum alloy, copper alloy and zinc alloy. Materials useful for titanium alloys; internal structures (electronic parts, clutch assemblies, emergency opening, Figure 3) include copper alloys, plastics, stainless steel, and the like. At present, our main concern is the lock body, and the materials of the panel and the handle. This paper also focuses on the analysis of the material of the lock body, the panel and the handle. The main processes involved include die casting, powder metallurgy, drawing, stamping, cleaning, polishing, electroplating, and machining.

Figure 1: Schematic diagram of the lock body (from the network)

Figure 2: Panel, handle diagram (from the network)

Figure 3: Internal structural accessories (from the network)

Second, the material of the lock body

We first look at the lock body is the role, he is mainly faithful to implement the opening and closing mechanism of the lock, is one of the main guarantors of safety and durability, and is also one of the core parts of the intelligent door lock, its material requirements It is durable and strong. Therefore, the main material of the current lock body is mainly made of iron and stainless steel and some zinc alloy. Copper is mainly used on the bolt, and the inner part is rarely made of copper. All stainless steel is expensive and difficult to process, but the price is very expensive. The general application process is mainly casting, stretching, cold pier, etc.; iron is the best cost-effective in lock body use, so the current mainstream lock body is used. It is made of stainless steel for durable parts, such as bolts and square rod transmissions. These are made of stainless steel to increase durability and reliability. Other parts use iron to reduce cost. The applied process is basically the same as stainless steel, and some are low. The price, all with iron or stainless steel, even in the tongue processing process using low-end powder metallurgy (high-end powder metallurgy parts are very good quality, the cost is also very high, some of the stainless steel also applies powder metallurgy, must be processed easily Some), low cost, but slightly less reliable and durable.

Figure 4: Locking parts

Figure 5: Square Rod Drive Components

Comprehensive review: All stainless steel > comprehensive > iron

Third, the material of the panel

This is the most concerned by many consumers at present, and it is also the most discussed. Generally speaking, the material of the smart door lock refers to the material of the panel, which is also visible to consumers. For example, the material of a star is plastic, that is Refers to the material of the panel, and the quality of the panel and the processing technology directly determine the two important indicators of the panel's firmness and durability. It is also the most important embodiment of the appearance value.

The materials currently used on the panel mainly include the following: iron, stainless steel, copper, aluminum alloy, zinc alloy, plastic, glass, and the like. Generally, the main material is rarely seen with plastic and glass.

1. Stainless steel, generally called stainless steel panel mainly refers to 304 stainless steel, individual 316 medical grade, 201 and 403 of two types we call pseudo stainless steel, in fact, is a kind of iron, do not comment on this aspect as smart door lock panel One of the main materials used has high hardness, high strength and low material price, which have natural advantages in terms of anti-violence and cost, but processing difficulties are its natural disadvantage. Generally, the thickness of the stainless steel panel is about 2.0mm, and the processing technology is mainly applied to bending, stretching, water grinding, polishing, electroplating and individual precision casting processes. Moreover, because of its material characteristics, stainless steel determines the current extremes of the panel. On the one hand, the minimalist and complex shape stainless steel panel is the most costly, and the lowest cost in the middle. For example, the smart door lock of Figure 6 is a minimalist representative. There is only one bending process plus surface treatment process. Due to its minimalist shape and tempered glass, the yield is less than 60%. This is a typical case. At the same time complex shapes, such as the stainless steel shape of Figure 7. Therefore, although the fingerprint lock slide type is popular among consumers, it is rarely made of stainless steel because the process is too complicated. However, it is rumored that several large stainless steel processing companies are now conquering.

Differentiate between stainless steel and non-stainless steel panels. Try it with a magnet. 304 and 316 can't be sucked.

Integrated stainless steel panel material smart door lock application

Advantages: durable, simple surface treatment, high reliability, strong corrosion resistance, surface damage, low cost and moderate weight.

Disadvantages: Difficulties in forming

Price: in the middle of all materials, individual high.

Comprehensive assessment: the simple choice of the smart door lock, the complex appearance waiting for technical breakthrough.

Figure 6 minimalist stainless steel smart door lock

Figure 7: Stainless steel panel with complex shapes

2. Aluminum alloy. There are a lot of names, space aluminum, magnesium alloy, and pure aluminum, but in general, all of them are made of aluminum as a base material. The material is light, moderate in strength, easy to form, and moderately priced. In fact, it is also one of the ideal materials for smart door locks. The main application process is die casting, extrusion, machining, surface treatment and other processes. The thickness of the general panel is concentrated at a thickness of 2 mm, and the thickness is selected to be thicker for individual strength. Its characteristics are that it is easy to form, the surface treatment is relatively difficult, the precision of die-casting or machine-molding is very high, and the pressure of environmental protection is high. Do you not see things in Wenzhou in previous years? It is because the aluminum metal is active during the polishing process, encountering open flames, and do not know why, the current market consumers think that the intelligent door lock of aluminum alloy material is the low end. (Of course, many companies used aluminum to save costs, but it does not mean that aluminum alloy panels are low-cost, many high-end products are made of aluminum alloys).

Materials that distinguish zinc alloys from aluminum alloys are generally not easily distinguished from the appearance and are distinguished by weight.

Comprehensive review of aluminum alloy materials in smart door lock applications:

Advantages: moderate cost, easy molding, easy coloring, easy processing, surface oxide layer is not easy to fall off, light weight!

Disadvantages: environmental protection pressure, market acceptance is poor, surface treatment is relatively difficult, corrosion resistance is poor, material strength is general;

Price: high and low extremes, low occupation of the mainstream

Comprehensive review: also look at the future market acceptance.

Figure 8. Aluminum alloy door locks

3. Iron, here I also include the so-called stainless steel (201 or 403 materials) and ordinary iron in our sense. In fact, in the era of mechanical door locks, iron is the largest user of door lock applications, in fact, strength, surface treatment, Although not as good as stainless steel, it is the most economical and cost-effective, but in the era of smart door locks, iron is surpassed by other materials. Especially zinc alloys. The most expensive iron material is generally composed of an iron frame and other materials. Generally, the intelligent door lock panel of the iron substrate is mainly used for stamping and surface treatment processes. Its surface treatment, molding process and processing technology reside between zinc alloy and stainless steel. Die-cast ferroalloy panels are cumbersome and have not found applications on smart door locks.

Distinguish whether it is a material panel of iron. In fact, there is no need to distinguish between them. At present, I have not found very few ferroalloy applications. I really want to distinguish the available magnets. The suction must be iron.

Comprehensive review of the application of iron on smart door locks:

Advantages: high strength, sufficient weight, general molding difficulty, centering treatment, electroplating centered;

Disadvantages: general strength, complex materials, surface corrosion resistance;

Price: not much application, price is not transparent

Comprehensive assessment: living in the middle is very embarrassing.

4. Copper and alloy materials. We generally refer to 59 copper alloy, which means brass, because of the white copper (65 copper nickel alloy hardness comparable to stainless steel, the price is several times that of stainless steel, very little application, pure copper is copper, soft, not suitable The manufacturer's panel is also not considered.) I personally think that it is an environmentally friendly and durable material. It is ok in terms of molding, surface treatment and strength. However, there are not many applications on smart door locks. The main processes of panel processing include gravity casting, forging, polishing, electroplating and other processes. Generally, the surface treatment of copper alloy is better than that of zinc alloy, and the surface coloring is easier. However, it is not easy to make complex shapes for the forging process, and the process requirements are complicated, but the cost of the mold is low.

The method of distinguishing between copper and alloy panel materials, the panel is turned over, the general copper panel is thick, at least 2MM, and the interior is generally natural, brass color!

Comprehensive review of the application of copper and alloys on smart door locks:

Advantages: easy molding, easy surface treatment, sufficient weight, strength to meet the requirements of use, consumer acceptance;

Disadvantages: The cost is high, and there are few manufacturers studying copper technology.

Price: slightly higher than the high end of zinc alloy, the overall price is not as high as expected

Comprehensive assessment: If cost control is obtained, research is in place and the development potential is great.

Figure 9, copper panel

5. Zinc alloy, general zinc alloy We mainly refer to the 1.2.3.5 zinc alloy material, and its cost-effective advantage has led to the current dominant in the intelligent door lock panel material, occupying an absolute mainstream share. Its advantages such as easy processing, easy molding, low cost, mature surface treatment, etc. make the zinc alloy use the largest proportion in the field of intelligent door locks. The main application processes are die casting, polishing, electroplating, machining, and the like. At present, most of the mainstream first-line brands use zinc alloys. Zinc alloy is currently the most researched material in the industry, but there is no one, but the price gap is also very large, the highest can be more than half, mainly the difference of zinc alloy materials. The good zinc alloy is the No. 3 and No. 5 zinc alloy. The imported one is more expensive. The domestic one is cheaper. The tonnage of the die casting machine is generally 280, 400 tons. The surface can be processed well, then the 0, 1 zinc alloy is even recycled. Zinc alloy, such a zinc alloy, is definitely a 150-ton die-casting machine, the surface is not easy to handle, and the interior is easily oxidized, which greatly affects the use.

The method of distinguishing the zinc alloy, the panel is also turned over, the inside is gray, or the visible traces of coloring, generally zinc alloy, of course, the weight should be sufficient. Different ways to distinguish between good and bad, look at the surface treatment, touch the surface by hand, no burrs, no surface peeling off, then look at the anti-light against the strong light, and let the anti-light move, if it is straight, smooth, it should be good.

Comprehensive Review Zinc Alloy Panel Fingerprint Lock Application

Advantages: easy molding, mature technology, good acceptance and moderate strength.

Disadvantages: difficult surface treatment, unevenness

Price: high, medium and low end complete

Comprehensive assessment: it will not be replaced by other materials in the short term, and will occupy the mainstream position.

6. Plastic materials, such materials are generally auxiliary materials, such as the password recognition part of the smart door lock (fingerprint lock). The general application of us is called acrylic material, and currently there are all applied plastic materials, such as in Xiaomizhong. One of the fingerprint locks raised is the acrylic structure of the steel skeleton on the curved surface (a kind of plastic), and the panel material of a certain star uses a large amount of plastic material.However, on the whole, it is still in the position of accessories, and has little effect on performance.

7. Glass, mainly used on the identification panel, is currently not found on the glass-based fingerprint lock panel market. I believe that it will not be discovered in the future, and it will be too fragile.

Comprehensive comment: All kinds of materials have their own advantages and disadvantages, mainly depends on the psychology of consumption and their own needs, there is no demand for materials that are not satisfied, this is the current status of smart door lock material application!